3.3 Weld characteristics

3.3.5 Stainless steel

High alloy steel in which the main alloy component is Cr or Cr and Ni

- Characteristic

- Corrosion resistance

- Heat-resistant

- Stainless classification

- Ferrite type

- Martensitic type

- Austenite type

- Cr content 18 [%] and Ni content 8 [%](lower limit 7 [%])

EX: SUS 304

It is difficult to generate cracks due to the same metal-to-metal welding, so welding is easy

Selection of welding rod and welding knowledge are indispensable for welding between dissimilar metals

3.5 Covered arc welding rod

3.5.1 Selection of coated arc welding rod: omission

3.5.2 Covering material of welding rod and its function: omission

3.5.3 Type of coated arc welding rod

- Classification of coated arc welding rod by purpose

Classified according to JIS Z 3211- Type of steel

- Steel plate thickness

- Welding position

- Types of structures

- Specification for welding rod

- Notation "E ***_{0} **_{1}-***_{2} **_{3} *_{4} *_{5} ***_{6}"

- E: Symbols for covered arc welding rods

- ***_{0}: 2 or 3 String of tensile strength against weld metal

- **_{1}: Sequence for type of covering material

- ***_{2}: String of major chemical components to weld metal

- **_{3}: String of welding heat treatment post treatment

- AP: No need for post-heat treatment or post-weld heat treatment

- P: With heat treatment after welding

- Not applicable: No post heat treatment is required

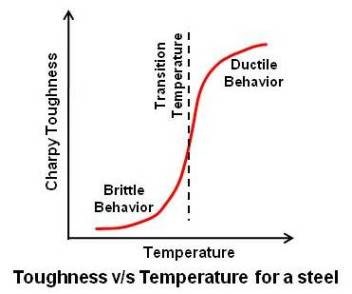

- *_{4}: String for Charpy absorbed energy

- U: 47 [J] or more at the prescribed test temperature

- Not applicable: Not less than 27 [J] at the prescribed test temperature

or not subject to the impact test regulation

- *_{5}: String for Charpy impact test

- L: -40 [^{\circ}C] or less

- Not applicable: -40 [^{\circ}C] beyond

- ***_{6}: Other additional strings for welding

- H5: Hydrogen content contained per unit mass of weld metal \leqq5 [ml] / 100 [g]

- H10: Hydrogen content contained per unit mass of weld metal \leqq10 [ml] / 100 [g]

- H15: Hydrogen content contained per unit mass of weld metal \leqq 15 [ml] / 100 [g]

- EX: KOBELCO E4319

Note: Bar diameter: core wire diameter- E

- 43: Tensile strength 43 [N/mm^{2}]

- 19: Illuminate type

- ***_{2}: Not applicable

- **_{3}: Not applicable: No post heat treatment is required

- *_{4}: Not applicable

- *_{5}: Not applicable: -40 [^{\circ}C] beyond

- ***_{6}: Not applicable

- EX: Charpy impact test

- Temperature [^{\circ}C]

- vE [J] Charpy Toughness

最終更新:2018年12月10日 05:05